Processing of engineering thermoplastics

Materials

Thermoplastics in industry

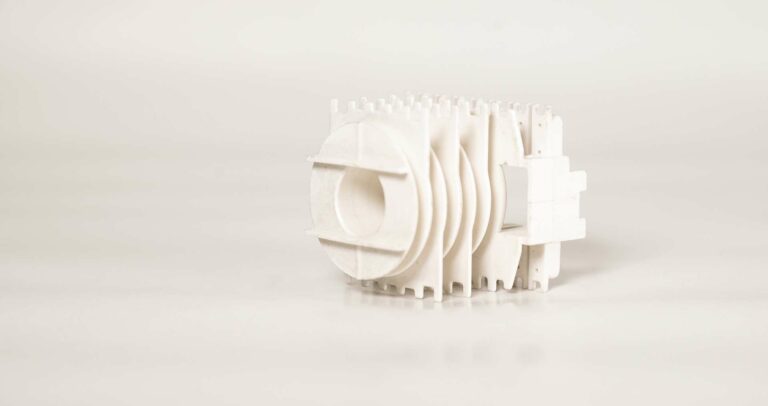

Thermoplastics are the materials with which we work the most in the Grávalos Group, and they are also among the most widely used in the industry. Their main advantage is that when heated they melt and can flow and, when cooled, they solidify to give shape to all types of final injection and induction parts.

Throughout more than 75 years of experience, we have been able to acquire a wide experience in the processing of engineering thermoplastics, which allows us to satisfy highly demanding and complex requirements from our customers.

The most common thermoplastics are polyethylene (with low and high density variants), polypropylene, and polystyrene. When better properties are required, whether mechanical or thermal, we turn to engineering plastics, also called high-performance plastics. These include materials such as polybutylene terephthalate (PBT), polyphenylene sulfide (PPS), polyamides (PA) and polyacetal (POM).