Technology

Automatic assembly and control

Automatic assembly and control

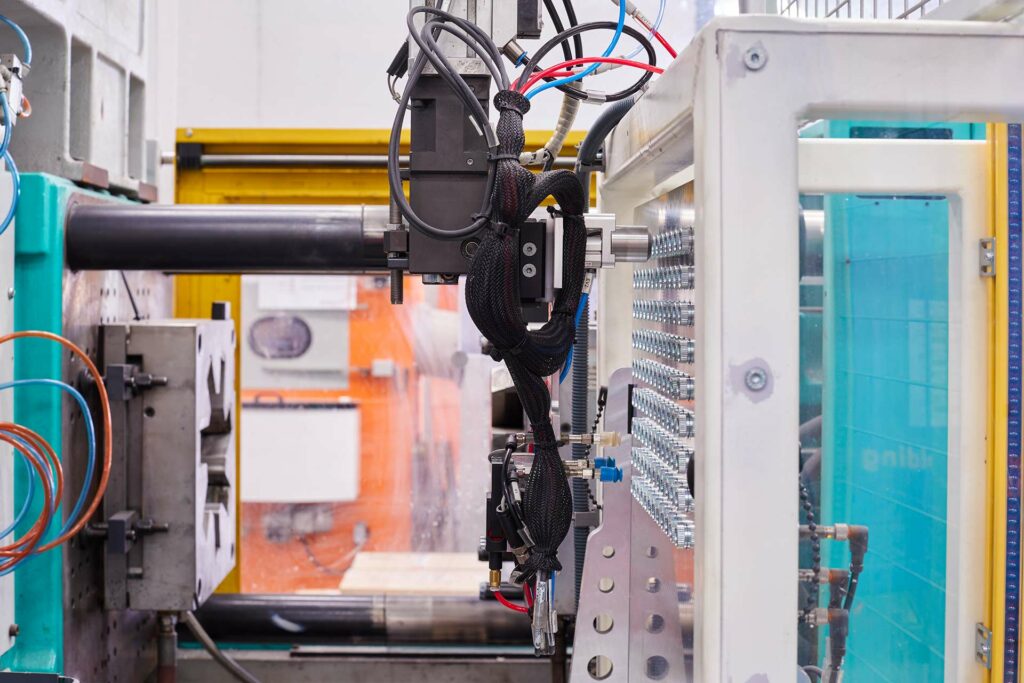

The manufacture of technical assemblies for use in industry requires modern automatic assembly and control lines.

Within this manufacturing concept, our group contributes great value, since we manufacture the subcomponents that are part of these assemblies, and we design and manufacture the assembly lines.

Our Technical Office, in collaboration with the Production and Maintenance Departments, designs the mechanical and automatic systems that make up these lines.

Technologies such as electronics, pneumatics, sensors and robotics are widely used by our expert team, so that in the assembly of technical assemblies we can achieve high manufacturing rates, while satisfying the most demanding quality levels.

AUTOMATION FOR HIGHER QUALITY AND COST OPTIMIZATION

In general, our automatic lines also require human intervention (they are semi-automatic in nature), although we also have lines that even perform the packaging fully automatically.

Thus, in the case of a semi-automatic line, two people are involved: one feeds parts to the machine and the other performs quality control tasks.

In the automatic ones, on the other hand, it is a robot that extracts parts from an injection molding machine and deposits them on an assembly line, which discriminates those that do not meet the quality requirements, and proceeds to their packaging.

Success stories

Opening of the first subsidiary in poland

Increase of the company’s production capacity at international level, starting to implement filter technologies close to the consumer plants and bi-component injection. …

Gravesa S.A.R.L., our new subsidiary in Morocco

Opening of a factory in Morocco to assist the customer in its supplier globalization strategy including the “Best Cost Countries”. …

Implementation of a digital warehouse management system

Transformation of the manual management system of a warehouse to a digital one, capable of managing its operations in a computerized way. …

Why choose us?

We make technical injection and induction parts, through complete solutions ranging from initial analysis, industrialization and homologation, to final manufacturing and transportation to any location.

01.

Humanization

We maintain the same interlocutor throughout the project lifecycle

02.

Machinery

Highest level of machinery and technology in all processes

03.

Professionals

Our entire team is specialized in what they do

Materials

Materials

Throughout more than 75 years of experience, we have been able to acquire a wide experience in the processing of engineering thermoplastics, which allows us to satisfy highly demanding and complex requirements from our customers.

PBT (Polybutylene terephthalate)

Case studies